johnofchar

Deceased VSRI Administrator

Former Member

10/19/03 1511 Hours

Posts: 11989

SV-Strom & K9 ABS Wee

Charleston SC USA

|

ib Your original post I quote here also refered to your new solution costing one third the money of others. Now that part has gone??? "It will work nicely and will last as long as your modifications for1/3rd of the money  " I removed that part of the sentence & now it's back since you brought it up.  |

|

|

|

|

Logged

Logged

|

“Most of the stuff people worry about, ain't never gonna happen anyway.”   Get your flags Get your flags |

|

|

|

Bolzen

|

Re: Modification of clutch baskets in the Macedonian manner

«Reply # 52 on: Today at 19:52:12»

Vujce, the English attack your modifications in the international forum. As it would disintegrate after a week of driving.

Otherwise, the character I really hate, hard to the evil god.

"Ride Crazy , What could happen...?"

Sounds like an eavesdropped wireless message  |

|

|

|

|

Logged

Logged

|

|

|

|

agolac

11/11/08 2133 Hours

Posts: 157

DL650A K8 85 000 km

Rijeka, Croatia

|

I agree with you sharealike. Don't worry, I'll make sure that valid arguments do not stay in the dark on Croatian forum. Keep up the good work. I really enjoy reading your posts  |

|

|

|

|

Logged

Logged

|

Flames of the end inside us rest...

|

|

|

|

|

agolac

11/11/08 2133 Hours

Posts: 157

DL650A K8 85 000 km

Rijeka, Croatia

|

ib

Later edit -I went to look for the pictures and write-up from past SV modifier who went this route. These spacers were dropped because one of the post's cracked at the base.

Sharealike. Could you please post forum link with this spacer on post modification. I'd like to read more about this modification |

|

|

|

|

Logged

Logged

|

Flames of the end inside us rest...

|

|

|

realshelby

09/28/09 1955 Hours

Posts: 953

'12 '04 Wee, '03 Vee

Houston, Tx

|

Time to get the thread back on track.....

A few months back I wrote that I was about to do some testing on the baskets and would report the good and bad of it. To be honest I didn't get very far the first time around. I had been running what I called the “Hybrid” design which had a new bearing installed in the aluminum basket with a flange machined in to center the inner plate. While that was also a unique design I also utilized a unique way of “fixing” the inner plate. I welded the holes around the baskets post and ground them to a perfect fit around the posts. I also welded up the thrust faces of the “window” where the springs go and hand fitted each window to an exact fit. This basket also had six of the hardened shims ( in this case hardened washers like I use in the shim mod ).

After reading that shims were not necessary in a basket that had a fixed plate and good bearings in place I thought I would try to run this basket without them. I had noticed and posted about a vibration in the 4800-5200 rpm range that I would like to improve. There was some conjecture that the shims might move some harmonics from lower rpms to that rpm range so that was another reason to run it without the shims. Also I thought the upper rpms might not be as smooth as they could be. Long story short, I ran the basket without shims and was very disappointed to feel slight chudder return in the 3-4K range! But, it was ever so slightly smoother in the higher rpms. I made one more teardown of the Vee and reinstalled 3 shims instead of no shims or the 6 shims like I had just tested. Chudder was slightly better but still there, upper rpms were slightly better than I remember it was with 6 shims.

I didn't like my results. If the new bearing and fixed plate makes the basket like new, is there a chance that there is slight chudder in a new basket? After talking to some owners that had installed new baskets and a few owners running modified baskets ( of different styles ) I found that most would admit there is still slight chudder in new and modified baskets. Now before you start flaming me know this: 99.9% of the riders would assume the slight chudder I am describing as normal. Especially if it didn't get worse. The problem with the factory design is that it DOES get worse in most cases. But, once you understand what chudder feels like and live with it a while you can detect it where others not familiar would not. So, I knew what I had been doing with baskets still left room for improvement. I decided to think these things over from a different angle and see if I could find something that controlled the vibrations better.

Several months later I am about to post what I came up with. But first I want to list some information about the testing I completed after the new design. While I hesitate to call it a “revelation” in design, what I came up with is like no one else has tried or even mentioned. One thing that led me down this path was the desire to build a basket without using shims. A lot of negative things have been said about them, I have had NO problems at all with any of the ones I have done. One has over 20K miles! But, that was my goal. What I came up with is a way to add a second bearing to the assembly! It is mounted to the top plate and supports the basket assembly from the opposite side of the steel gear as the aluminum basket bearing does. This second bearing stabilizes the whole assembly. In fact, it made a bigger difference in smoothness than any single thing I have done since the 1st shim mod! Smoothness in the upper rpms was notably better. My 4800-5200 rpm vibrations were much better. BUT, from about 2800-3800 rpms under certain conditions I could still detect slight chudder. So I decided to do some more testing...........

During this ordeal I made NO changes or adjustments to my Vee at all. 16/43 gears, never touched the synch on the throttle bodies. I had a route that I used for each test. My test for chudder was always in the same place, a hard right turn onto a ramp on the toll road. Roll around the corner in 2nd gear and apply about 1/3 throttle. I could only get it to chudder in 2nd and 3rd gear under just the right circumstances and it was very slight. On another area of the toll road with a slight grade I could test for chudder in the 4-5K range in 6th gear, a place where I could feel it in other baskets. I am condensing the results as I sometimes repeated combinations to verify results. I had the basket out/in over 15 times just to test. Sometimes twice in one day! Tests below were the same basket which has a brass bearing in the aluminum basket, a “fixed” plate, and the new second bearing installed in the top plate.

No shims: Slight chudder in the 2800-3800 range rolling on the throttle in lower gears. Upper rpms were the smoothest with this combination.

3 shims: placed in the first and second stage springs. Chudder was there in the same range as no shims, but was notably less. Close to as smooth in upper rpms, you could feel the vibes of the engine in the 5K range.

“Trick” springs: I done this by mistake! I had reversed the placement of the springs ( red or third stage where the other springs go ) when going back to “no shims” to compare. This seemed to completely eliminate the low rpms chudder! But, it allowed a noticeable amount of engine vibrations to be felt in the 5K and up range. Just not as smooth even in lower rpms ( vibrations and chudder are different ).

6 shims ( .050” thickness ): this combination allowed almost no chudder to be felt in the lower rpms. But it was not quite as smooth in the upper rpms as the no shim and 3 shim baskets. Like the trick spring package it just allowed a bit more of the engine vibrations to be felt thru the basket than the other combinations.

6 shims ( .043” thickness ): this is what I am running now and what is in most of the baskets testing the new design at this time. In my opinion it is the best compromise. Most riders would never notice chudder with this combination and the upper rpms are very smooth, not much different from the no shims combination.

I ran each of these combinations at least 3 times ( except for the .050” shims ). I remember one time coming in after a test loop ( about 20 miles ) and immediately taking the basket out, tearing it down, putting it back together with a different combination, and reinstalling it in just over an hour!

I am satisfied that I have done about all I can to build a basket that works better than a new one and lasts longer than a new one. Sure, you could build billet parts and continue upgrading that way but costs would get in the way. While I did not want to have to build using the shims my testing shows me that they are better for the way most would use a Vee. For those that want a basket without shims, no problem, the new design is great without shims. But for anyone that spends most of their time under 5,000 rpms the shims are a better way to go! More on the new basket coming....

|

|

|

|

|

Logged

Logged

|

WERKS modified clutch baskets available HEREQuestions about clutch basket modifications? E-mail Terry here: info@werksparts.com |

|

|

PeterW

10/14/05 0631 Hours

Posts: 982

DL650 L2

Gold Coast, Australia

|

Just a comment, check and see if there's a spring manufacturer near you. Making the springs slightly longer will have the same effect as the shims and is essentially zero risk - nothing can fall out then  , my suspicion is that the existing design with loose springs is simply done so that assembly is cheaper. I have a DL 650 so don't have an axe to grind here, but I have had springs manufactured to spec. in the past and it was surprisingly inexpensive. Pete |

|

|

|

|

Logged

Logged

|

|

|

|

realshelby

09/28/09 1955 Hours

Posts: 953

'12 '04 Wee, '03 Vee

Houston, Tx

|

Pete, I have a source for springs but have not went that route yet. One of the other owners that has been modifying baskets and I have had a LOT of dialogue back and forth about this very thing. Yes, if we could decide on exactly the right spring ( uggghhhh, more testing! ) it might mean a drop-in improvement. While I mentioned shims above I did not go into detail about them or the actual design of the new basket.

The shims I am using in the full-tilt basket jobs is a true shim, not just a hardened washer ( which is perfect for the "shim mod" ). I machine the shims with a .150" step in the center. The diameter of this step is machined just right to fit inside the springs. No way for them to come out, and there is no reason or need to weld the retainers on the top plate as with the shim mod baskets. Machined from tool steel and then hardened/tempered. These are showing virtually no wear and I have confidence they are a permanent solution.

|

|

|

|

« Last Edit: 03/13/11 1251 Hours by realshelby »

|

Logged

Logged

|

WERKS modified clutch baskets available HEREQuestions about clutch basket modifications? E-mail Terry here: info@werksparts.com |

|

|

swingset

Captain of the Short Bus

04/09/09 0108 Hours

Posts: 50

DL1000K3

Central Ohio

|

I'm running one of Realshelby's new modified baskets. Although mine is a 2003 (early style) and may have required some work not present in later baskets, I will attest that the shudder is, in every way that matters, essentially gone. Low RPM chudder and vibes, are honestly better than when the bike was new, and in the upper RPM's the bike is smooth like a Swiss sewing machine, I hadn't really realized that chudder was present up in those RPM ranges until getting the basket back. Now I definitely feel where it used to be.

I'm keenly aware of the difference between my chuddering Vee and a new one, have a friend with a brand new bike so as mine got really bad I was swapping his to get a sense of where mine was problematic and how it should be on a new bike. I haven't had the chance to compare my bike with his again, now the new basket is in it, but I honestly think it's smoother now than his new bike with a new basket (under 5k on it).

I can't say much on longevity or durability, I only have a few hundred miles on it but the initial impression could simply not be better.

|

|

|

|

|

Logged

Logged

|

|

|

|

Sharealike

Clutch Re-Engineering for VStrom, KLV and SV

01/22/09 2020 Hours

Posts: 393

|

I'm running one of Realshelby's new modified baskets. Although mine is a 2003 (early style) and.....

I'm keenly aware of the difference between my chuddering Vee and a new one, have a friend with a brand new bike .....

I honestly think it's smoother now than his new bike with a new basket (under 5k on it).

I can't say much on longevity or durability, I only have a few hundred miles on it but the initial impression could simply not be better.

Swingset - If by "new modified" you mean it has a rebuilt centre bearing and inner plate fastened firmer than new. Then it most likely will feel more refined than a new bike. Please compare with your friends bike and report back if you can. We know a new basket stands SOME chance of having mild chudder. A new bike may even have mild chudder. A SLIGHTLY higher chance it has some detectable by 5k miles. Think back to the stripped brand new baskets some of us linked to on Youtube with their loose inner plates and the sloppy inner bearing. Every new basket in about ten (and all years of manufacture) I stripped to modify had these loose - without exception. The bad chudder creeps in slowly as this initial loose plate chudder worsens and wears the bearing out of true. I only know of two cases in 150 modifications where the owner said it struck over night. To be clear. I am not suggesting all bikes need this modification. Owners know when the annoyance makes it worth the change. Forget about the chudder zone and take a ride with the rev counter covered. Only the bad chudder worth attention should annoy. Just for the record for those following. Other than the inner plate that can crack, Suzuki made no other material change between your "early style" basket and the later years up to 2010. Early inner plates are often fine - just so long as the fix method takes the concentrated load off the area that cracks. I have spare inner plates if required but the engineered modification is the same for all styles. Sharealike |

|

|

|

|

Logged

Logged

|

|

|

|

realshelby

09/28/09 1955 Hours

Posts: 953

'12 '04 Wee, '03 Vee

Houston, Tx

|

Just for the record the basket Swingset is running is my "second bearing" design. No pictures or much information has been posted about this design yet. I have asked the owners running this basket to refrain from posting till they get a really good feel for how it is doing! I have one owner that is currently running a brand new Suzuki basket and has been waiting till he gets about 3,000 miles on it to change it out. We built his basket about the same time he bought the new basket so he would have a good baseline to compare performance between them. As I posted earlier this second bearing design I have developed really seems to make a noticeable difference in the overall smoothness of the modified baskets. Possibly better than new. Obviously Swingset is so happy he has to sit on his hands to keep from clapping  . |

|

|

|

|

Logged

Logged

|

WERKS modified clutch baskets available HEREQuestions about clutch basket modifications? E-mail Terry here: info@werksparts.com |

|

|

swingset

Captain of the Short Bus

04/09/09 0108 Hours

Posts: 50

DL1000K3

Central Ohio

|

Sorry, didn't mean to jump the gun!

|

|

|

|

|

Logged

Logged

|

|

|

|

|

|

rancur3p1c

01/22/11 1619 Hours

Posts: 26

sv1000s

atlanta

|

Realshelby, have you or Sharealike looked into the center steel sleeve that fits inside the bearings, directly on the shaft?

When removing mine to send to Sharealike I took a good gander at it, mentally noted the wobbles, and while applying force to the clutch basket, noticed that the area BETWEEN this sleeve and the shaft had just a bit of play in it! I'd say that would be worth investigating. Once I get my basket back I'm going to look at the wobble that exists there again and decide if I want to order a new one.

|

|

|

|

|

Logged

Logged

|

|

|

|

realshelby

09/28/09 1955 Hours

Posts: 953

'12 '04 Wee, '03 Vee

Houston, Tx

|

I can't speak for Sharealike but yes, I have looked into that. I posted a small amount of info on it. What started the process was the newer version of the bearing has one less set of rollers. Remember, the basket doesn't turn on that bearing/shaft while underway. I think it is only when the clutch lever is pulled in while the tranny is in gear. Feel free to correct me on that. What I found is that the old style bearing is slightly tighter than the brand new replacement bearing! While I won't say it has no effect, I don't know what could be done to tighten it up. In fact, once it is up to temperature as the bike is running and has oil on it, there may be little or no measureable movement. I think we are on the right track to eliminate all problems with the basket. I would be surprised if the bearing you are talking about is really a factor but I have an open mind about it.

|

|

|

|

|

Logged

Logged

|

WERKS modified clutch baskets available HEREQuestions about clutch basket modifications? E-mail Terry here: info@werksparts.com |

|

|

Sharealike

Clutch Re-Engineering for VStrom, KLV and SV

01/22/09 2020 Hours

Posts: 393

|

"I can't speak for Sharealike but yes, I have looked into that. I posted a small amount of info on it.... I think we are on the right track...."

IMHO and to make it clear to those who follow - WE are on very different tracks so far as basket modifications go. Now I will try to find a kind way to say you either did not read the question from rancur3plc, or did not understand it. Realshelby, have you or Sharealike looked into the center steel sleeve that fits inside the bearings, directly on the shaft?

When removing mine to send to Sharealike I took a good gander at it, mentally noted the wobbles, and while applying force to the clutch basket, noticed that the area BETWEEN this sleeve and the shaft had just a bit of play in it! I'd say that would be worth investigating. Once I get my basket back I'm going to look at the wobble that exists there again and decide if I want to order a new one.

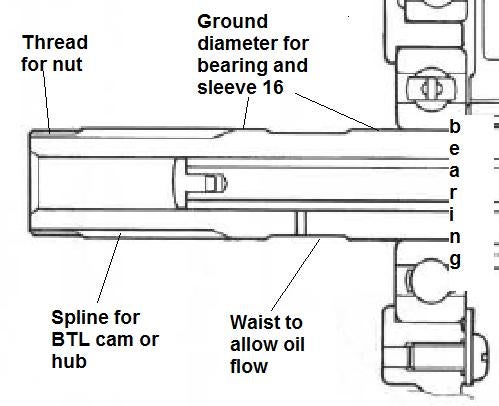

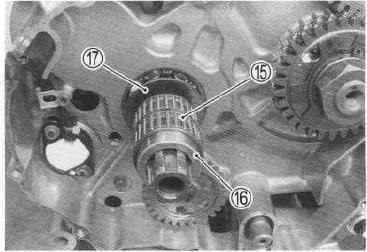

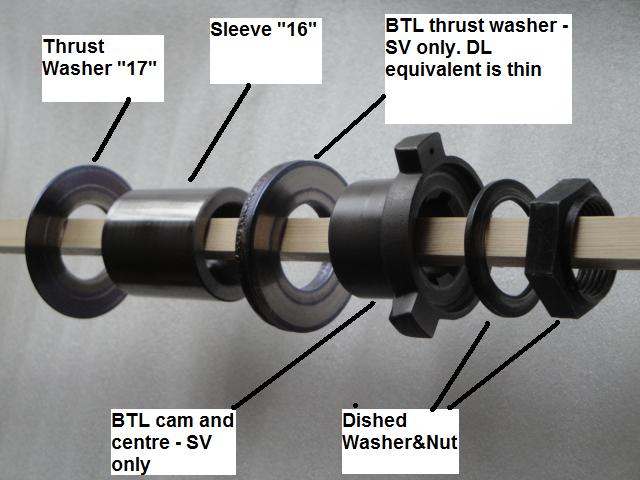

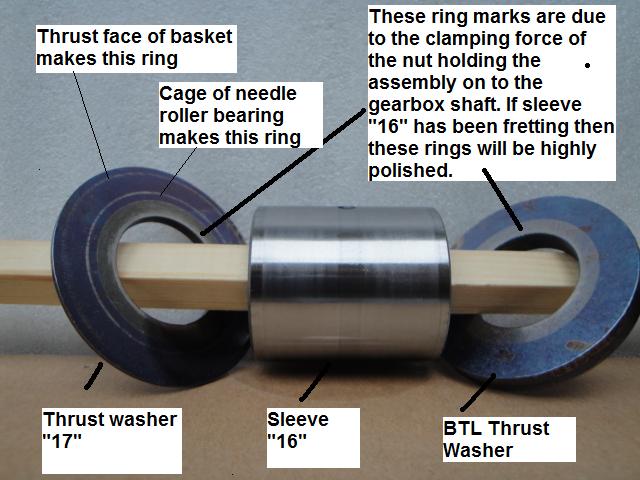

Hello rancur3plc A very relevant question and something owners changing a basket can be checking to be certain they get maximim benefit from my modification. Both SV and DL that is. No bike here with the cover off just now so will have to make do with some "library" pictures to explain. There is a gap or some play as you decribe. The sleeve can be lifted up and down on the gearbox shaft. Thats with a perfectly good shaft and even with a new sleeve. This is the bare shaft sticking out of the gearbox. It's a very good fit in the ball bearing that supports it. You can see how the same ground diameter that the bearing fits on is extended so that the sleeve 16 is supported on the shaft. Note the waist to allow oil circulation to the needles.   Now the shaft being fitted with thrust washer 17 and sleeve 16 (the sleeve the needle roller runs on). The sleeve is not all the way to the bearing and thrust washer face here.  Here we see the full set of components in order as they go onto the gearbox shaft. These are SV parts. The DL has the clutch hub in place of the SV BTL cams shown here. The nut clamps all these parts tight against the inner race of the gearbox bearing. None of them are a very close fit on the shaft diameter - but just close enough. Care as you tighten the nut can make a difference but without the sort of ground taper fits such as on a flywheel the fact is the BTL cam (clutch Hub on DL) and sleeve will not be perfectly concentric about the shaft.  Check here just in case that sleeve in the middle of the bearing is fretting and contributing to the vibrations. Here's the sleeve and two thrust washers showing the normal marks from the clamping effect of the nut. If the marks are polished then I would suggest the sleeve has been fretting about on the shaft. Probably due to the nut loosening slightly or riding for an extended distance with severe clutch chudder.  You only get a new sleeve 16 with a new basket. Its accurately ground inside and out to fit. I have never seen or hear of one being damaged inside or on the bearing face where the needle rollers run. I doubt there is room to introduce anything like a sleeve of shim steel that would fill the gap as a trial. A bearing or pinion lock type fluid would be a good solution but there are two drawbacks with that. Later strip down might be prevented and you have an oil route from the shaft centre out to the needle rollers which might block if not used with care. Another positive might be a slight stiffening of the shaft where it flexes just outboard of the bearing. I would only propose this if attempts at mounting the sleeve conventionaly proved impossible. sharealike |

|

|

|

« Last Edit: 03/16/11 1642 Hours by Sharealike »

|

Logged

Logged

|

|

|

|

realshelby

09/28/09 1955 Hours

Posts: 953

'12 '04 Wee, '03 Vee

Houston, Tx

|

IMHO and to make it clear to those who follow - WE are on very different tracks so far as basket modifications go.

Now I will try to find a kind way to say you either did not read the question from rancur3plc, or did not understand it.

sharealike

What made you think " WE" included you? A bit more humility would serve you well... Yes, I did read the question posed by rancur3plc. Yes I understood it perfectly. I have felt the play he mentioned. Many bearings have "play" at rest and are designed that way. Like I posted earlier, at operating temperature and with oil on it there may not be enough movement to be a factor in "chudder". So your "kind" way of telling me I am a dumbass isn't working. |

|

|

|

|

Logged

Logged

|

WERKS modified clutch baskets available HEREQuestions about clutch basket modifications? E-mail Terry here: info@werksparts.com |

|

|

rancur3p1c

01/22/11 1619 Hours

Posts: 26

sv1000s

atlanta

|

What made you think "WE" included you? A bit more humility would serve you well...

Yes, I did read the question posed by rancur3plc. Yes I understood it perfectly. I have felt the play he mentioned. Many bearings have "play" at rest and are designed that way. Like I posted earlier, at operating temperature and with oil on it there may not be enough movement to be a factor in "chudder". So your "kind" way of telling me I am a dumbass isn't working.

I'm not talking about the bearing, talking about part 16, the sleeve. Can't we all just be friends!!    |

|

|

|

« Last Edit: 03/17/11 0301 Hours by rancur3p1c »

|

Logged

Logged

|

|

|

|

realshelby

09/28/09 1955 Hours

Posts: 953

'12 '04 Wee, '03 Vee

Houston, Tx

|

rancur3p1c, I am talking about the whole assembly. Including where the "16" goes on the shaft. Because of how it goes on the shaft and the way it is held on I still think at operating temps there isn't much chance of movement between "16" and the shaft. But you should be talking about the bearing also. There is a chance of movement there and there is proof that Suzuki had a concern there also. That proof is the change in bearing design. There are other factors I don't want to begin to tie into this, such as how the torque from driving the steel gear on the basket might keep the bearing from moving. There is a way to make a basket perform better than new, and I expect there will be little interest in the pursuit of vibrations from the clutch area from here on out.

As for getting along, I enjoy conversations with owners like you and many others on this site and others. Sharealike burned his bridge a long time ago......

|

|

|

|

|

Logged

Logged

|

WERKS modified clutch baskets available HEREQuestions about clutch basket modifications? E-mail Terry here: info@werksparts.com |

|

|

Sharealike

Clutch Re-Engineering for VStrom, KLV and SV

01/22/09 2020 Hours

Posts: 393

|

What made you think "WE" included you? A bit more humility would serve you well...

Using my name with "I" in your first sentence of a paragraph. Then use the term "we are on the right track" in the same paragraph suggests we are working together. I make it clear to those who follow that we are not. Sorry if it's a bit blunt. Important for me to stress because so far you put your name to and introduced at least six different ways/attempts at eliminating this chudder problem. Yet now a secret seventh on the way. Need to be certain owners do not associate me with your often confusing changes and revisions IMHO. Fair I make it clear to those who follow and others hard up against this problem that my now long established engineered solution (not changed in all that time) is completely different, care how similar a description and choice of words you might make. Design was finalised over two years ago. Owners asked me to do the same for them and has been available to everyone for just over a year now. Just want to exchange concise and clear technical information about this whole vibration problem with everyone. The pupose of the thread. Sharealike |

|

|

|

« Last Edit: 03/17/11 1208 Hours by Sharealike »

|

Logged

Logged

|

|

|

|

realshelby

09/28/09 1955 Hours

Posts: 953

'12 '04 Wee, '03 Vee

Houston, Tx

|

I'll make it PERFECTLY clear for you. "WE" is the two individuals that have given their time and efforts in helping me with the technical aspects of doing a fully re-engineered basket. They have no interest in Motorcycles but have taken an interest in my project.

Talking about secrets, you still have not posted pictures of your old design.

The only comparisons I have made to your design is that you have a new bearing in the aluminum part of the basket and that you "fix" the plate in the proper position. My baskets have both of those improvements, although I have a completely different way of "fixing" the inner plate. I won't argue about which method is better, if they both work I'll leave it at that. As for six different ways of eliminating chudder, let us be careful of how we use the word "eliminating". If you are referring to the recent testing I have done, then I have tested several different combinations and posted the results. I am not satisfied with just a fixed plate and new bearing. Maybe you are. And since I have become convinced thru my hard work and testing that there is a better way to controll and virtually eliminate chudder I do not have a single basket combination that I have posted for a year or more about. Because I have been making improvements and integrating them as I go. But, I am about done as I think I have refined the baskets to the point where there is not much room for improvement. So if anyone is confused about my changes and revisions I hope they understand this has been a work in progress. I have not been doing these as a business so there was no point in advertising my work as it progressed.

"Fair I make it clear" to all owners running a Sharealike modified basket that I have never knocked his design. I am fairly sure it is a good basket and will give good as new service for a lot longer than a new basket. All I have asked is that the same respect be afforded me and my work. But....

One definition of insanity is doing the same thing over and over and expecting different results. I must be insane....as I know better than to respond to Sharealikes posts....yet here I am again hoping it will convince him to quit posting negative and false things about my work.......

|

|

|

|

|

Logged

Logged

|

WERKS modified clutch baskets available HEREQuestions about clutch basket modifications? E-mail Terry here: info@werksparts.com |

|

|

johnofchar

Deceased VSRI Administrator

Former Member

10/19/03 1511 Hours

Posts: 11989

SV-Strom & K9 ABS Wee

Charleston SC USA

|

That's about enough back & forth stuff. You guys ( mainly Sharealike & realshelby) please stick to answering questions form other members & posting about your own products. From what I see & know in the end we are going to have two good clutch fixes (not saying anything about the possible third) available to us & that is a good thing. So for now -  |

|

|

|

|

Logged

Logged

|

“Most of the stuff people worry about, ain't never gonna happen anyway.”   Get your flags Get your flags |

|

|

stromtruppen

11/05/10 2053 Hours

Posts: 3

DL1000K4

Monza, IT

|

Dear Sirs, I'm reading this discussion since from begin....sometimes very funny  I done clutch basket modification about 10.000 km (6500 miles) ago, now I have about 35.000 km ( 22.000 miles) and I can say to be satisfied of this small work, almost no vibrations or "chudder" as you call , better gear shifting and so on... What I done ? Only replaced all the springs inside and that's all.... I fully agree with PeterW from Australia , when I dismount the clutch basket "all" the springs where "dancing and ringing" in their seats, I knew somebody here in Italy already done this job, so I contacted him in Florence to have more informations on which spring he used for. This springs are standard dimension for plastic mould machine ( 20 D x 10 d x 25 l ) available in various strength , that fits perfectly even with a light preload, I used all the same, the strongest (yellow color), because I was worried looking the original and the new springs... In numbers : the new springs are 25 mm , the seats in the basket are about 23 mm, the original "dancing" springs rather 20 mm. I know....sorry I have no pics of this but I prefer to be alone when i do such jobs.... The last.....I apologise for my english, is very bad, I know, but all of you will understand anyway....  Regards from Italy Stromtruppen (Cesare) |

|

|

|

|

Logged

Logged

|

|

|

|

realshelby

09/28/09 1955 Hours

Posts: 953

'12 '04 Wee, '03 Vee

Houston, Tx

|

Cesare, that is good information!  I have similar springs where I work ( metal punching/forming dies ) and have wondered about installing springs like you mention. Seems that tightening up the assembly with longer springs or even the shims/washers I have used for the basic shim mod calm down the vibrations in a way that keeps the chudder from being a problem. Do you know what the strength of the springs were? Especially compared to the 3 different ones that come in the baskets? That would be helpful info. |

|

|

|

|

Logged

Logged

|

WERKS modified clutch baskets available HEREQuestions about clutch basket modifications? E-mail Terry here: info@werksparts.com |

|

|

stromtruppen

11/05/10 2053 Hours

Posts: 3

DL1000K4

Monza, IT

|

Hi Realshelby ! nice to read you, I would like to give my small contribution to a "final solution" for all vibrations, chudders, etc etc. this is what I used : http://www.specialsprings.com/molle_iso_eng.htmlin row 20 at the G there is the link : http://www.specialsprings.com/pdf/molle/G.pdfregarding the original springs, even if is possible to me, I think has no sense to measure the strenght , because in my opinion the material of this springs is "collapsed" Realshelby, I think there are two main reasons to the "vibrations" : clutch loseness and carbura...the air/fuel ratio at low rpm  For any help contact me Regards Cesare |

|

|

|

|

Logged

Logged

|

|

|

|

Sharealike

Clutch Re-Engineering for VStrom, KLV and SV

01/22/09 2020 Hours

Posts: 393

|

Cesare

These Die springs you propose are near direct replacements for the standard springs. They will be fitted with a pre-load of 1.55 mm - 454 N force. The person you contacted in Florence has calculated this accurately for you by measuring the standard springs. He had very good knowledge of them as the table below will demonstrate.

You are very near with your numbers for the spring sizes and seats. You state "In numbers : the new springs are 25 mm , the seats in the basket are about 23 mm, the original "dancing" springs rather 20 mm".

The seats in the basket gear are 23.45mm (not 23mm), the original springs are 23.3mm (not 20mm). The standard springs are always this length after 0 miles, 6,000 miles or 30,000 miles. In over 150 baskets there have been a handfull of springs that were slightly below this due to wear on their ends, not "collapsed" and only one that had broken. The baskets I take these measurements from range from brand new to those with 50,000 miles. The standard springs have proved to be of excellent quality and durability for the application.

The tables below compare full basket damper deflection load between Standard and proposed Die springs.

Standard Springs

Primary spring – 466 N/mm - 1 of these – Load at 3mm deflection = 1398 N

Secondary spring – 590 N/mm - 2 of these – Load at 2mm deflection = 2360 N

Third stage spring – 786 N/mm - 3 of these – Load at 1mm deflection = 2358 N

Total load at full damper deflection with standard springs = 6116 N

Series G Die Springs assuming pre-load of 2mm rather than 1.55mm to keep it simple.

Primary position – 293 N/mm – 1 of these – Load at 3mm deflection = 1465 N

Secondary position – 293 N/mm - 2 of these – Load at 2mm deflection = 2344 N

Third stage spring – 293 N/mm - 3 of these – Load at 1mm deflection = 2637 N

Total load at full damper deflection with Die springs = 6446 N

The Die springs will all be pre-loaded by about 2mm. This will make them slide permanently to one side in the windows of the gear and "lock" against the plate. They keep the plate from vibrating because they press heavily on it and keep the plate with the gear.

If you fitted them at 6,500 miles the centre hub would not have had time to wear too much so is probably responsible for the "almost no vibrations" you have. The loose plate will still be loose but loyal to the gear and still eating further into the aluminum with the ends of the new springs. The plate will also be wearing the back of the basket because it in now moves much more with the gear. The bearing surface between aluminium basket and gear is supposed to be steel running on steel. Not steel running on aluminum?

Die springs are far from the correct spring for this application. They are a softer rate for longer travel and perhaps not so many life cycles than standard. You proved they managed a good distance and so long as their material is compatible with the seats they run against, then they are certainly an improvement over washers/shims. Remains to be seen what they look like after a fair distance.

Sharealike

|

|

|

|

|

Logged

Logged

|

|

|

|

rancur3p1c

01/22/11 1619 Hours

Posts: 26

sv1000s

atlanta

|

that makes a lot of sense, springs locked like that wouldn't be good long term at all.

|

|

|

|

|

Logged

Logged

|

|

|

|

Leroy

02/15/11 2101 Hours

Posts: 113

DL1000K8

Kentucky, USA

|

Regardless of the approach that you'll use to fix your clutch basket, the first order of the day is to get the thing out of the bike and onto the work bench. David O'Brien's excellent photo series spells the process out as well as can be done. I didn't like the look of the Motion Pro clutch holding tool, however - it just didn't seem, uh, robust. Vince Goosey of GB Motorcycle Products sells what I consider to be a solid clutch hub holding tool. Here it is in action -  To paraphrase Paul Hogan in Crocodile Dundee, "That's not a clutch holding tool... now THAT'S a clutch holding tool." Minimal torque on the cheater bar was required to break the retaining nut loose, and I didn't need my neighbor's air impact wrench. You need one of these in your tool box. |

|

|

|

« Last Edit: 06/16/11 2033 Hours by Leroy »

|

Logged

Logged

|

|

|

|

|

ib

|

Where did you get this fancy cheater bar? [edit] - found a lot on eBay. Thanks for the hint. Bought both the clutch holding tool and breaker bar (630 mm long)  |

|

|

|

|

Logged

Logged

|

Genuine V-Strom Fundamentalist, VSRI 598 |

|

|

|

|

|

Bolzen

|

To paraphrase Paul Hogan in Crocodile Dundee, "That's not a clutch holding tool... now THAT'S a clutch holding tool." Minimal torque on the cheater bar was required to break the retaining nut loose, and I didn't need my neighbor's air impact wrench. You need one of these in your tool box.

Wait, was that the knife he spoke about? If I remember it right, he got some skills at handling that too  |

|

|

|

|

Logged

Logged

|

|

|

|

|

Your Privacy Choices

Your Privacy Choices